High Performance Disinfection, even for previously ‘Untreatable’ Liquids

NovoLabs™ patented Supercritical UV™ disinfection system provides unparalleled efficacy for a wide range of liquids including low and ultra-low clarity liquids & wastewaters. The disinfection system utilises a unique “top-down” ultraviolet light delivery system into very thin, very fast, flow hydraulics. Supercritical UV™ disinfection systems have repeatedly demonstrated pathogen reductions of up to 5 log in liquids of <1% UVT – with a single pass!

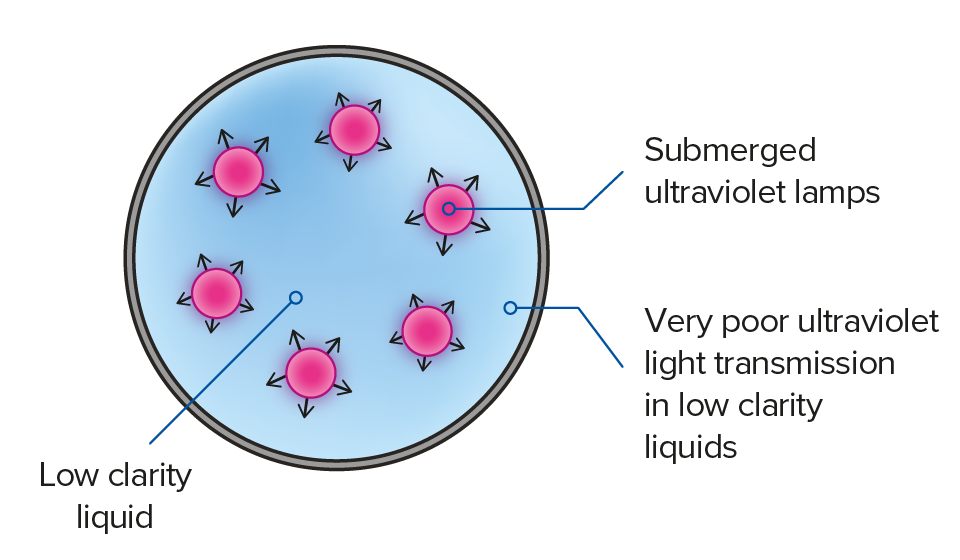

Legacy submerged lamp ultraviolet disinfection system

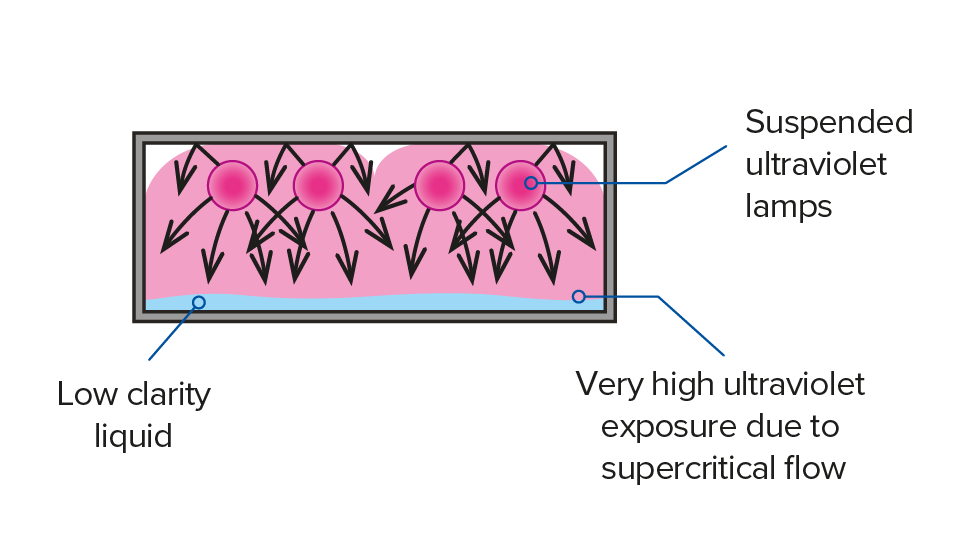

Supercritical UV™

disinfection system

The Difference is in the Ultraviolet Light Delivery System

Conventional ‘channel’ or ‘pipe’ ultraviolet treatment systems submerge ultraviolet lamps into the liquids where the germicidal light drops off at an exponential rate. The NovoLabs™ Supercritical UV™ disinfection system radically increases ultraviolet dose exposure throughout the liquid by radiating a thin, fast-moving sheet of liquid from above in a highly reflective treatment channel.

Supercritical flow in action

NovoLabs’ patented Supercritical UV Disinfection System can address treatment challenges and significantly reduce treatment costs for low clarity/low UVT process liquids and wastewaters.

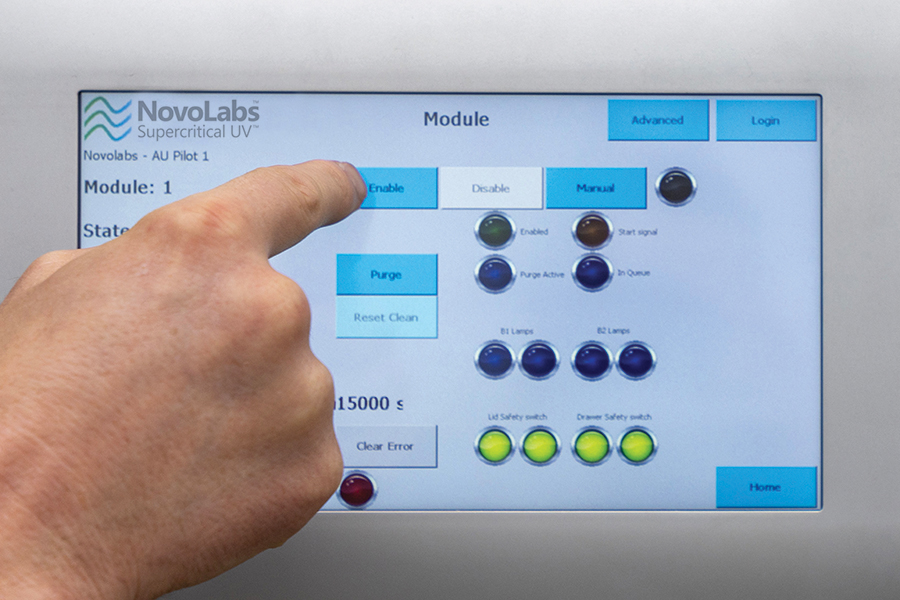

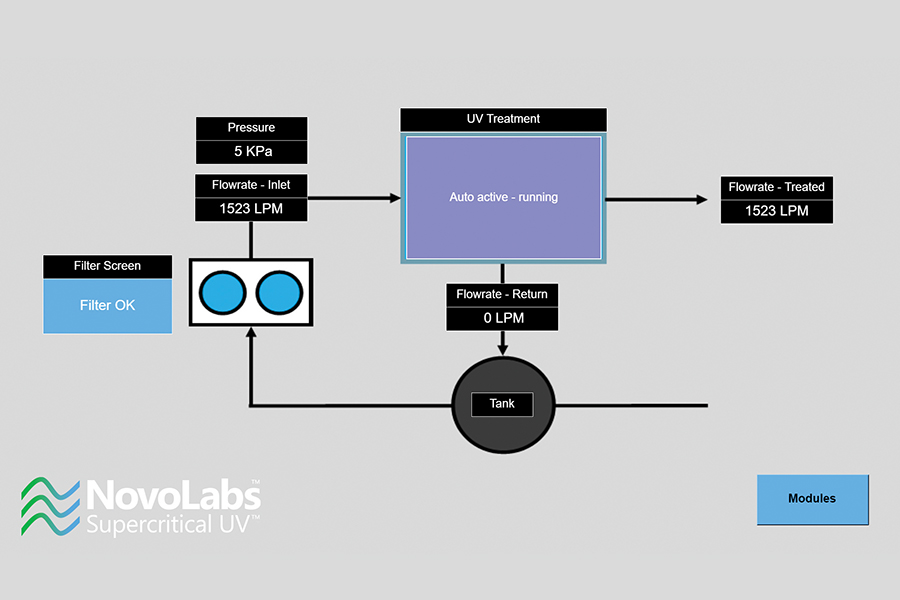

Peace of Mind with Parallel Processing

Because NovoLabs™ modules operate in parallel, any individual module can be safely deactivated and accessed for inspection or service while maintaining full flow throughout the rest of the system.

NovoLabs™ smart system continually monitors flow rates and system status and will auto-divert flow to another module in the event of a lamp outage — ensuring performance protection day and night.

Operator Safety & Ease of Maintenance

Modular Design for Easy Scalability

Powered to Your Requirements

The NovoLabs™ Supercritical UV™ disinfection system employs the highest quality, long-life, low pressure amalgam ultraviolet lamps that output an optimal spectrum of germicidal ultraviolet light. Each module is fitted with the number of ultraviolet lamps needed to provide the required output for your application.